Products

- Home /

- Products

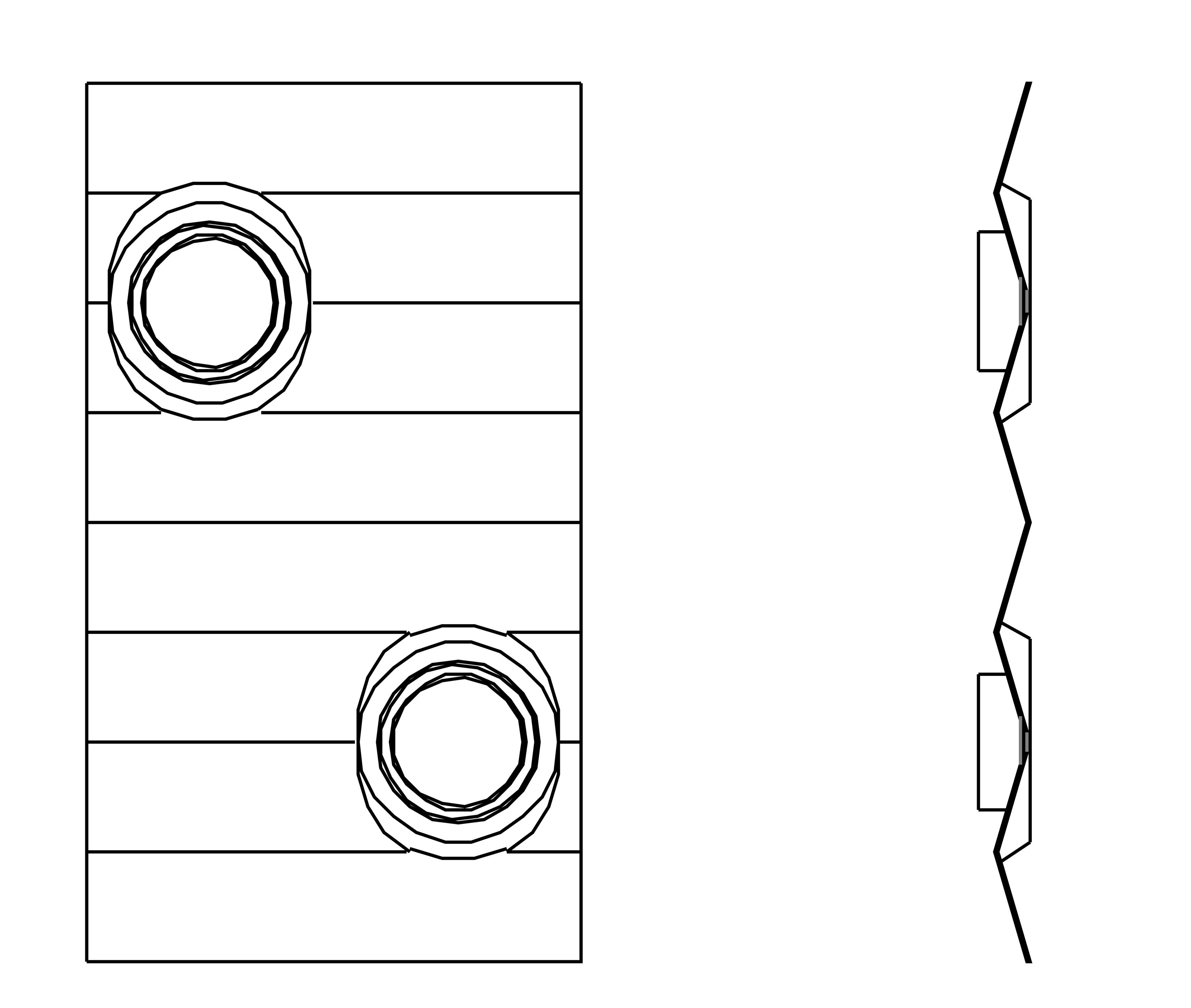

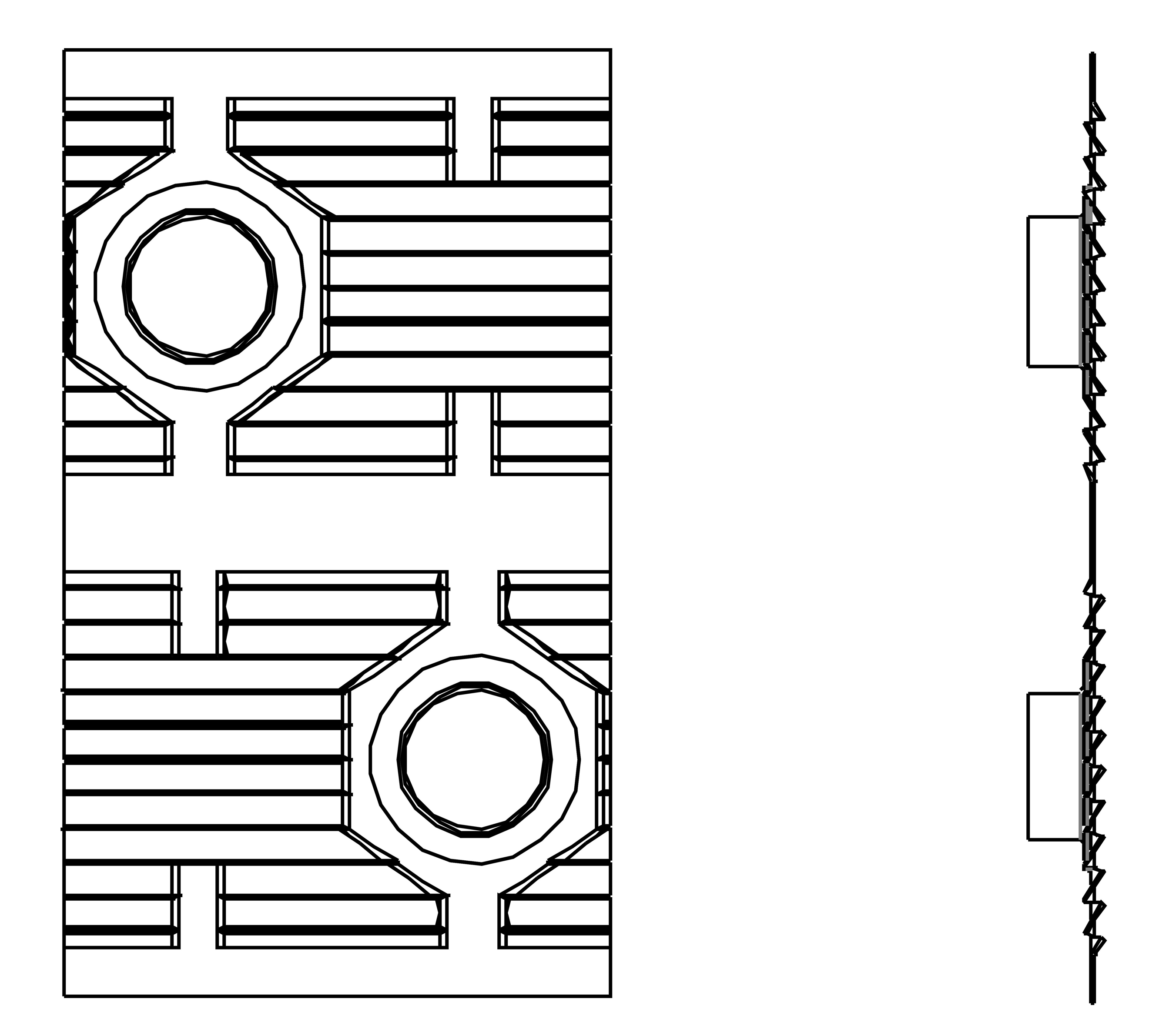

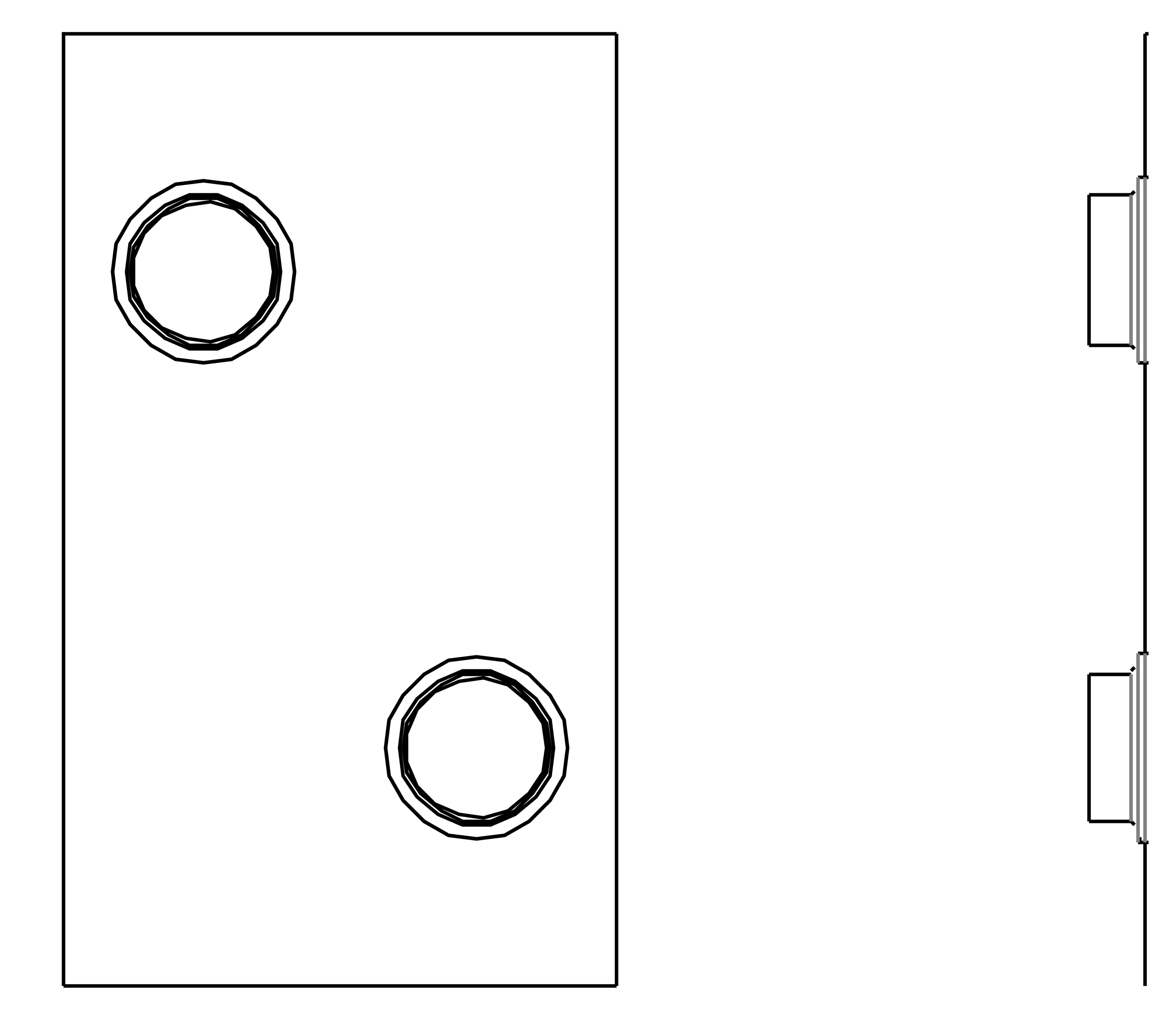

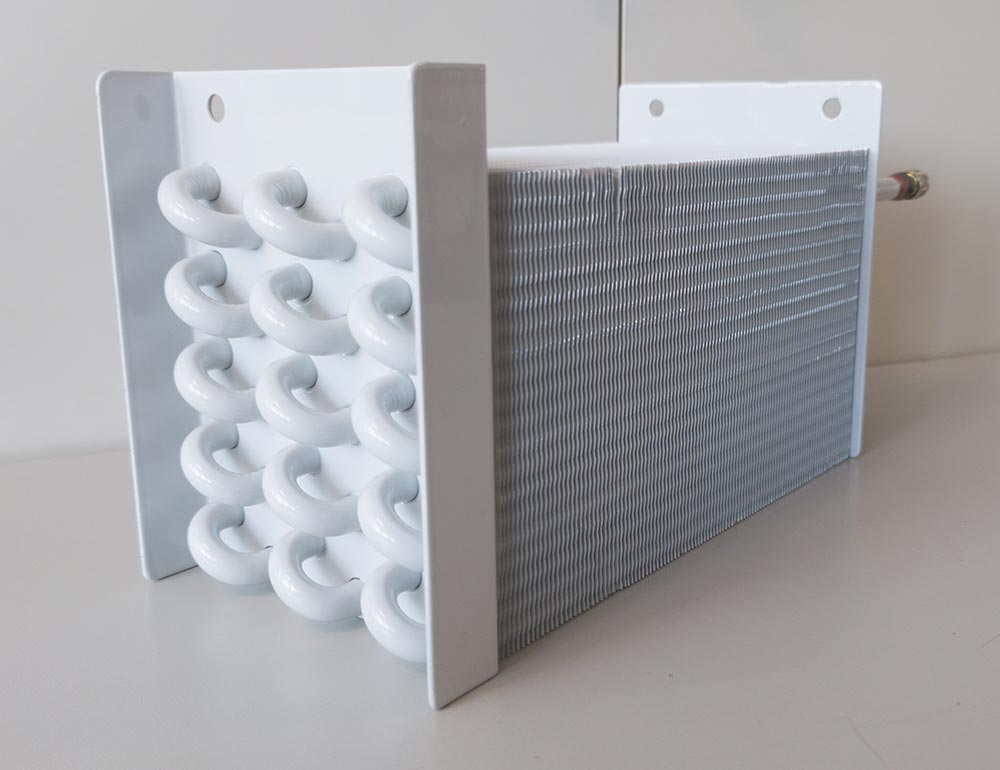

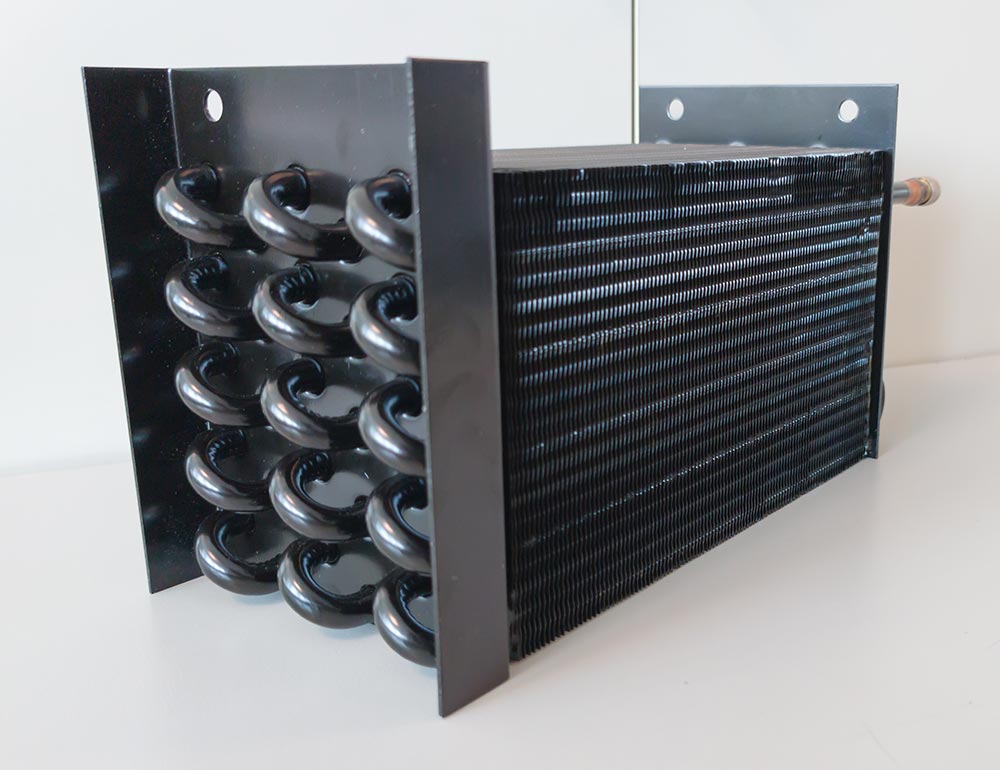

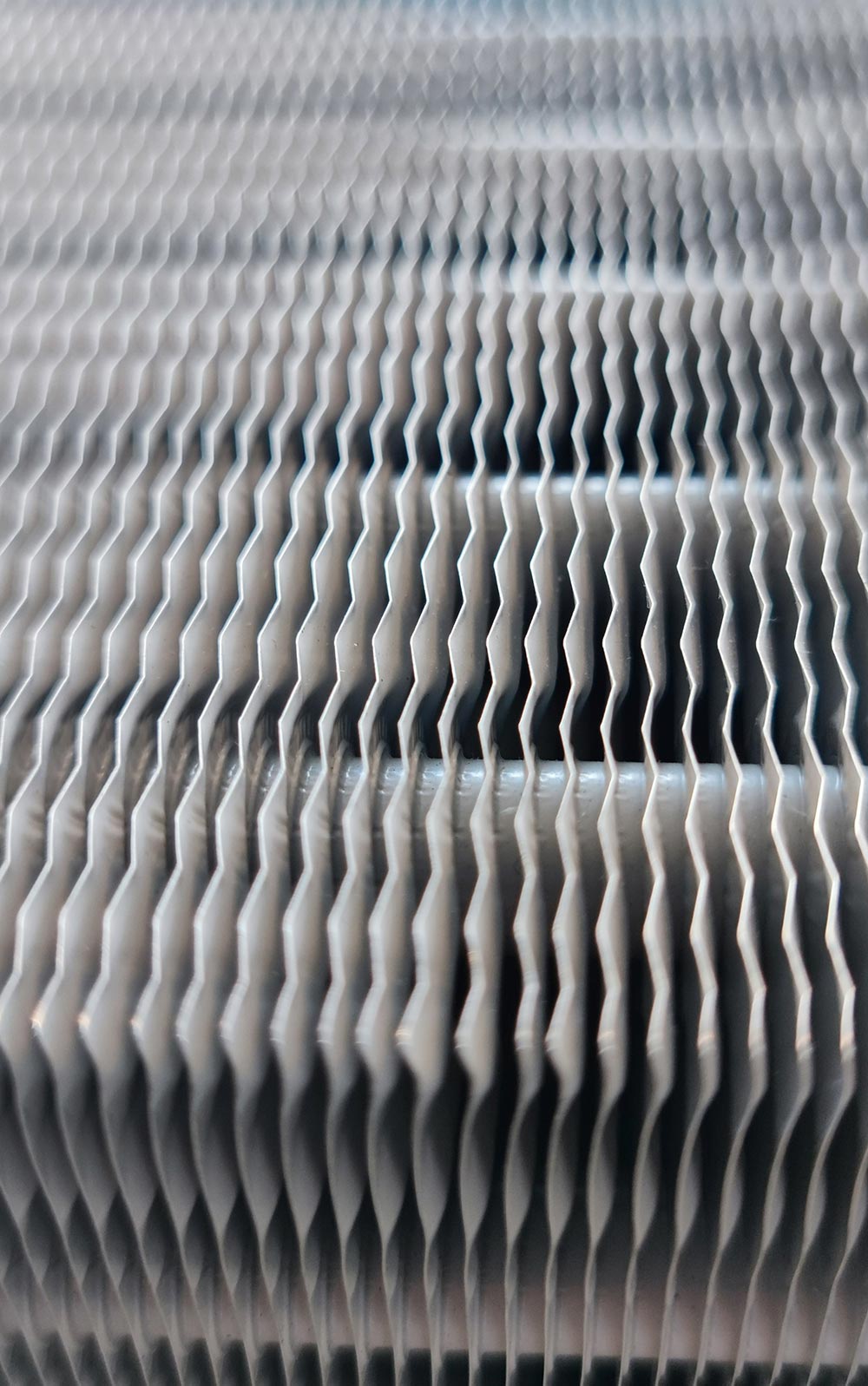

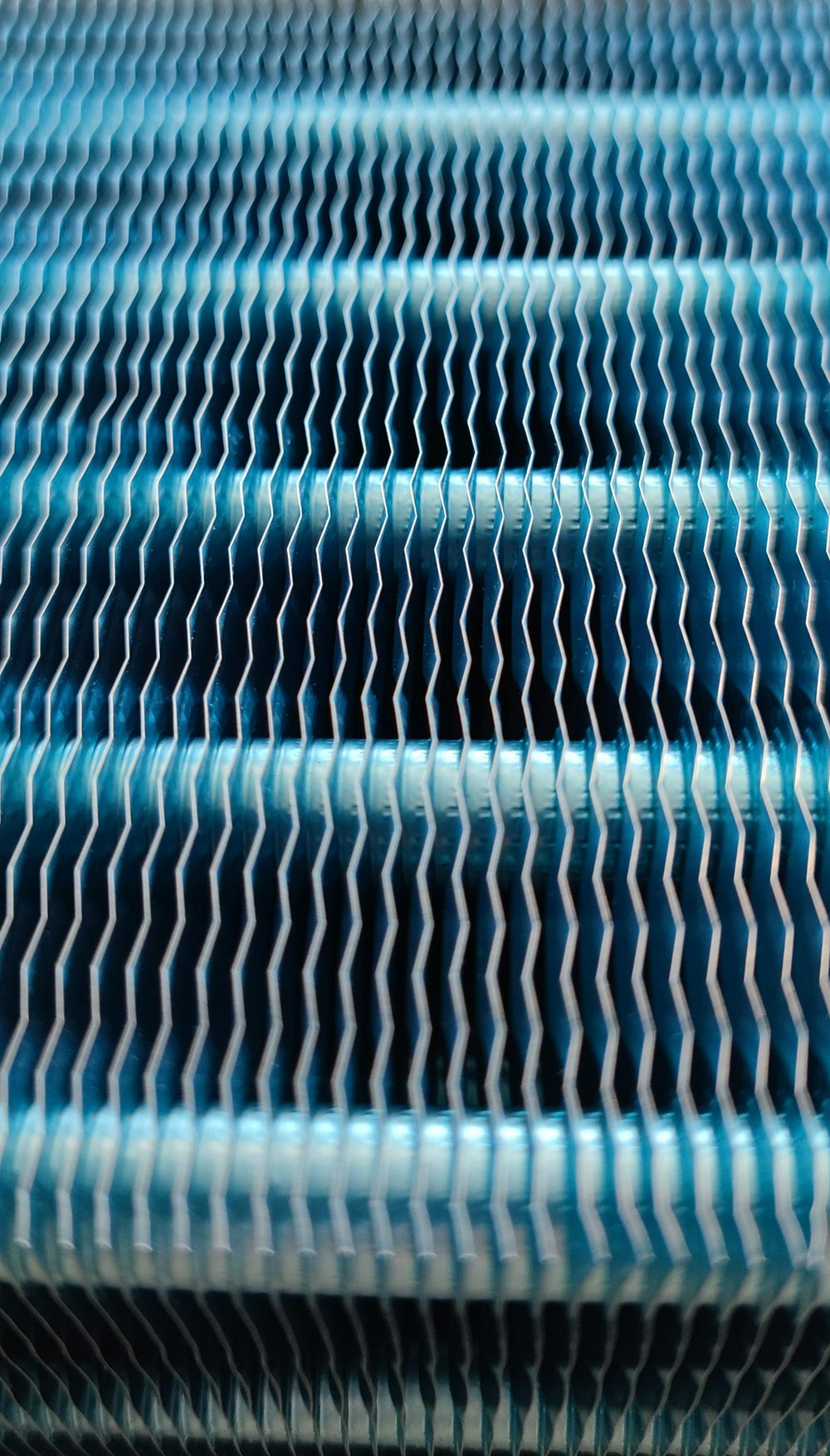

Finned pack heat

exchangers

Sierra manufactures finned pack heat exchangers that can be used in many different civil and industrial applications where heat exchange is required between air and primary fluids such as water, refrigerants, non-freezing solutions, etc.

Product Specifications

Construction Materials

| Tubes | Fins | Frame | Manifolds | Distributors |

|

|

|

|

|

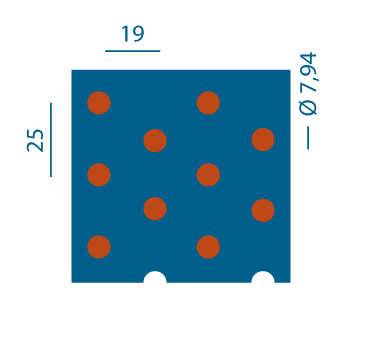

Constitutive Characteristics

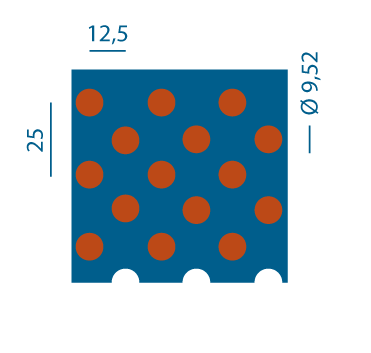

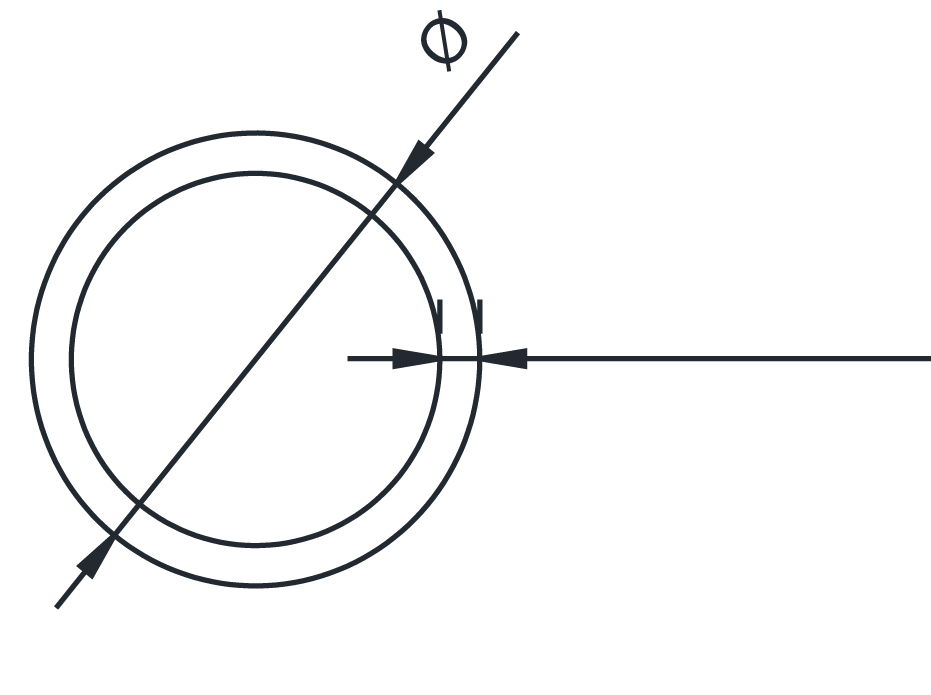

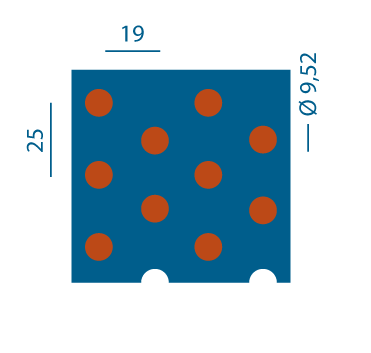

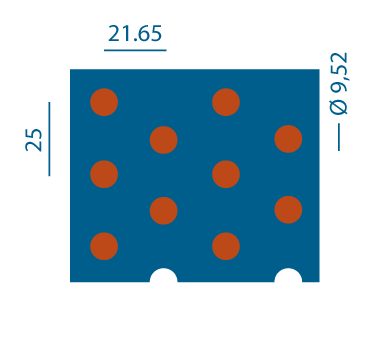

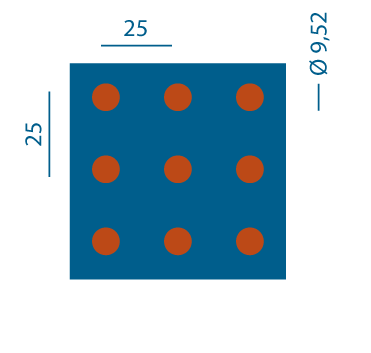

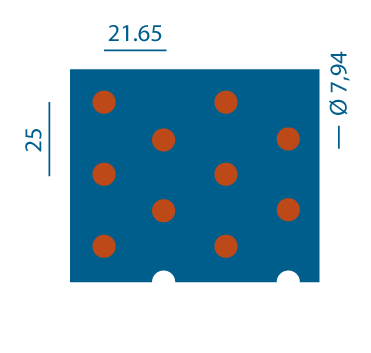

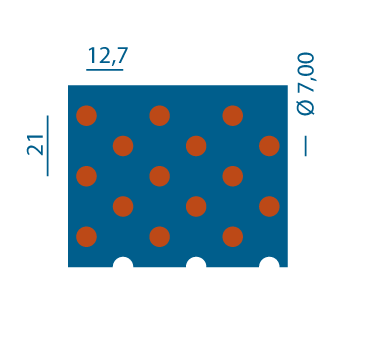

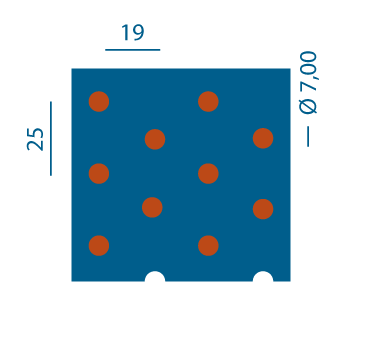

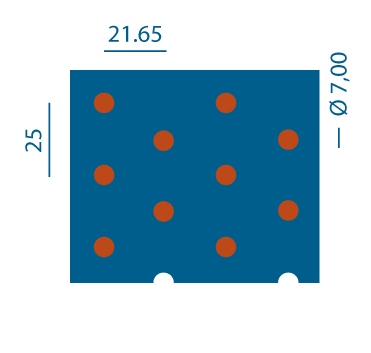

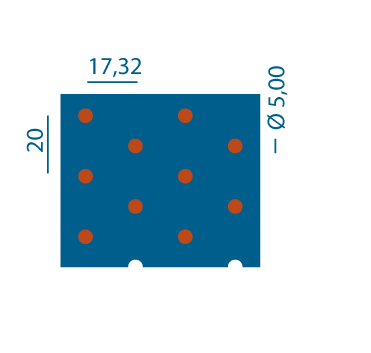

Outer diameter of the tubes and geometries

| Tube ø 5.00 mm | Tube ø 7.00 mm | Tube ø 7.94 mm | Tube ø 9.52 mm |

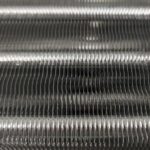

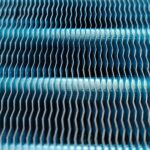

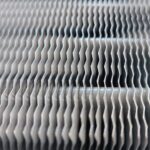

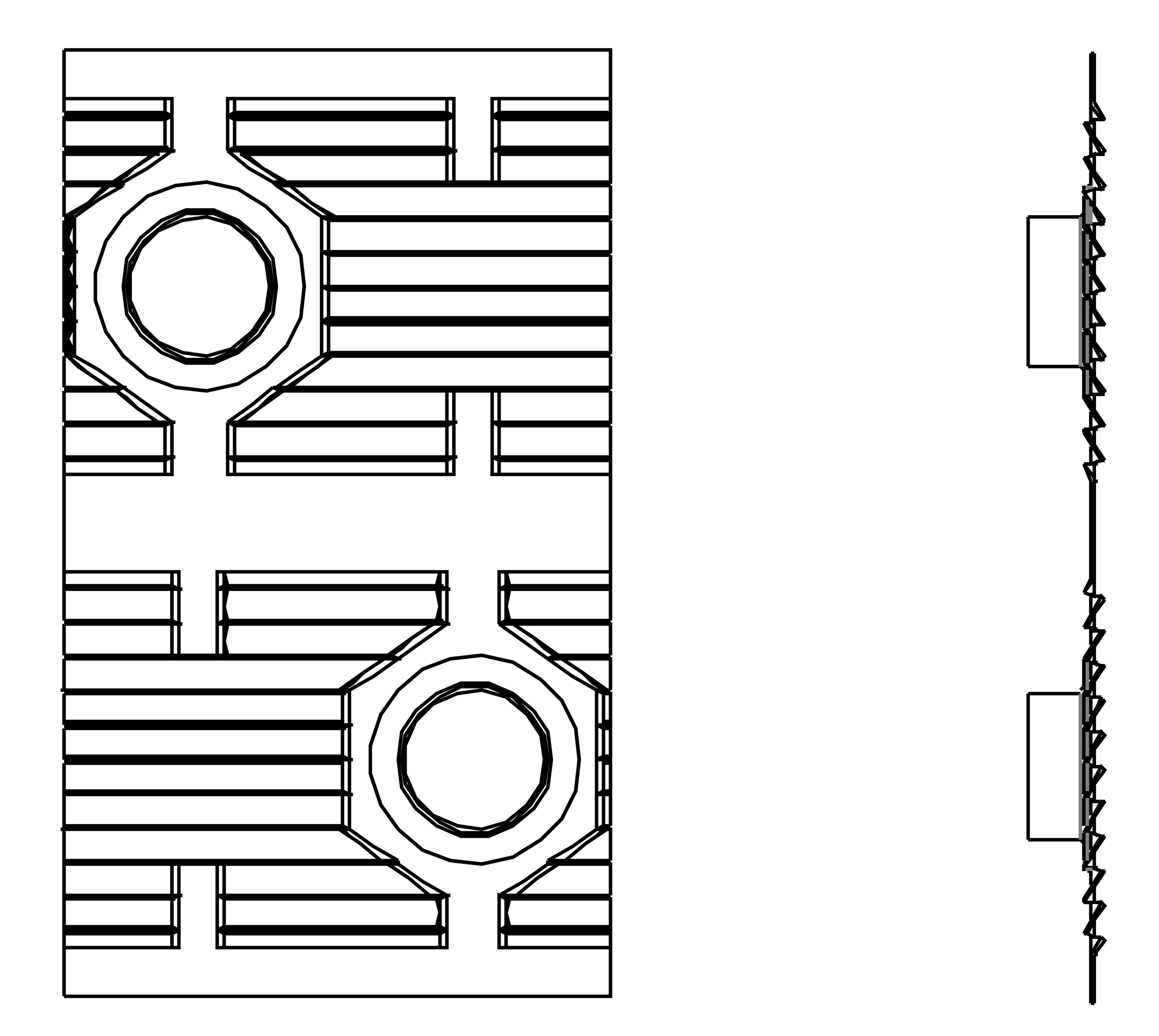

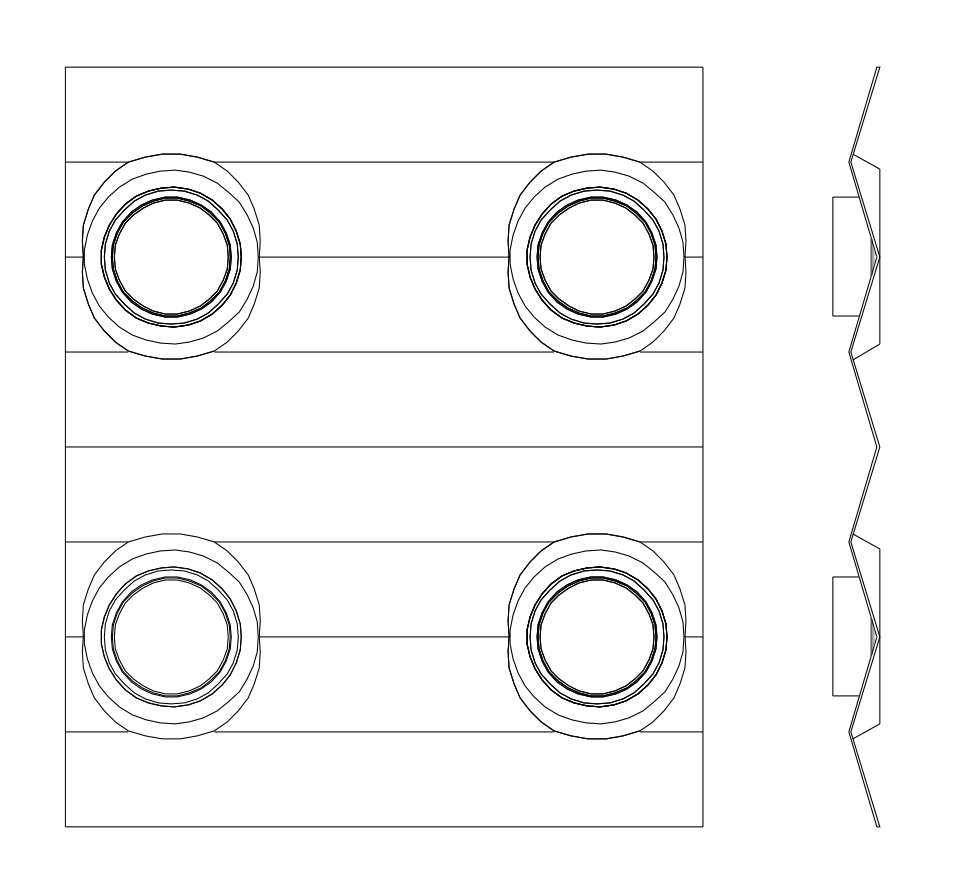

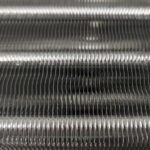

Fins and Types of Finned Packs

| Fins | Fin treatment |

|

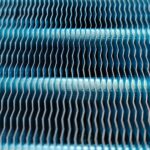

Surface Treatments and Types of Finned Packs

| Surface Treatments and Types of Finned Packs | Type of Finned Pack |

|